A series of filtration products from ink ingredients to finished product filling. The current products are used in a variety of ink filtration situations. There are suitable technical solutions and products for production from a few millilters to dozens of tons.

Brief Introduction

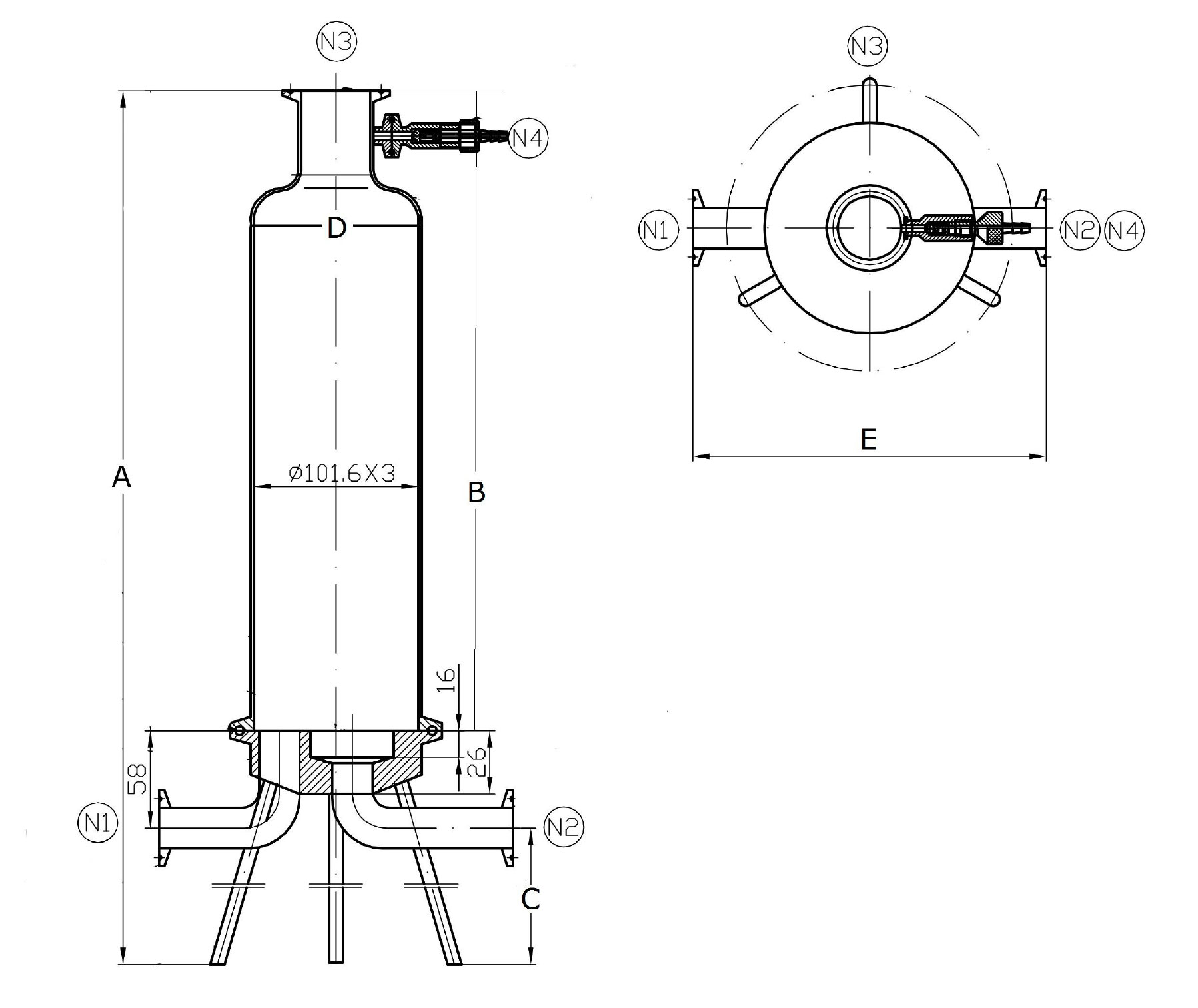

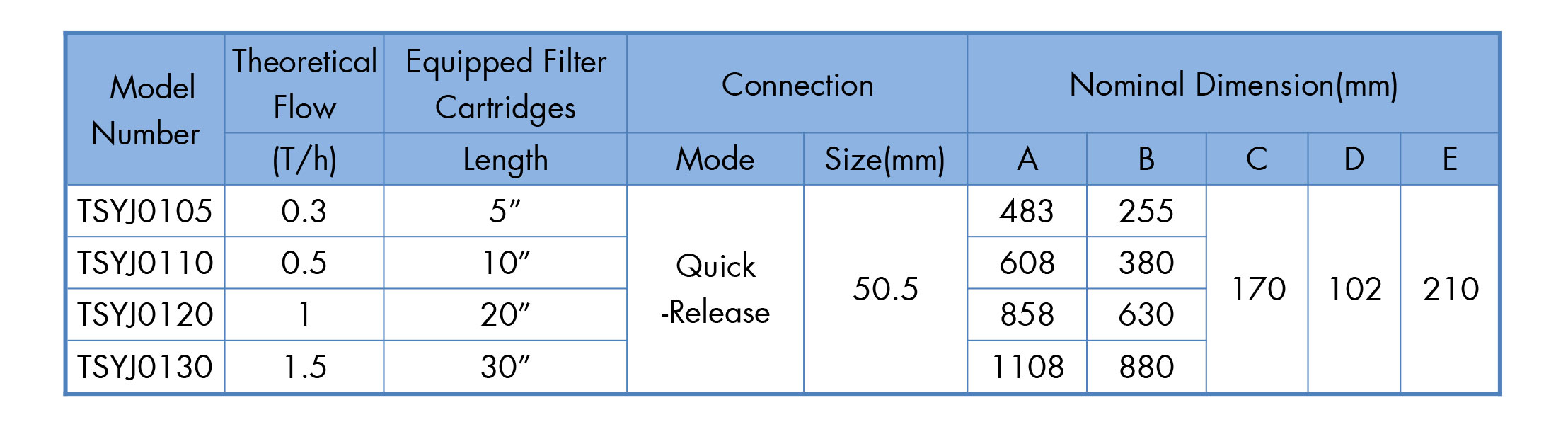

Accepts 5",10",20",30" or 40" length cartridge filter

Smooth, ultraclean surface finish enhances cleanability.

Thermal jacketed bowl available for steam or coolant circulation.

Sanitary design prevents entrapment or build-up of contaminants.

T-type flow configuration with inlet and outlet on the same centerline.

316L stainless steel construction gives max durability and corrosion resistance.

Quick-release clamp allows easy disassembly and fast cartridge replacement.

Sanitary vent and drain valves permit easy venting, draining,sampling or integrity testing operations.

1. Oil -based inks, made of nylon, has excellent organic solvent compatibility. Ratings: 0.1um, 0.22um, 0.45um, 1um, 3um, 5um.

2. Water-based inks uses PES membrane, has high flow rate and high precision. Ratings: 0.02um, 0.04um, 0.1um, 0.22um, 0.45um, 1um, 3um, 5um, 10um

For Ink Filtration

Deep pre-filtration( conventional PP, resin material, large dirt holding capacity, wide chemical compatibility and stable interception performance.

High -precision dirt-holding filtration(gradient pore size 0.3~100 micron filtration, high interception efficiency, dirt holding capacity, and long service life.

Material | 316Lor 304 stainless steel |

Surface treatment | Mirror polished or electrolytic polished |

Design pressure | 0.8Mpa |

Max. operating pressure | 0.6Mpa |

Design temperature | 20℃~150℃ |

Seal style | O-ring or flat gasket |

Barrel connection | Thread, hoop, flange |

Element connector | DOE, 222, 226 |

Thickness | 2mm |

Inlet/Outlet inner diameter | 1 inch |

▶Veterinary

▶ Food & beverage

▶ Biotechnology

▶ Medical & Medical device

▶ Laboratory

▶ Chemical and painting industrial filtration