Hydrophobic PTFE pleated filter cartridge whose filter membrane adopts natural strong hydrophobic PTFE stretched membrane has extremely strong corrosion resistance and oxidation resistance, and the support media is made of imported polypropylene material, which is made by hot melt welding without any Adhesive, no medium falls off. Our PTFE pleated filter cartridge is specially designed for sterile filtration of gas and exhaust, used in gas applications of microelectronics industry, biopharmaceuticals and biotechnology industries, including autoclaves, fermentation air intake, aseptic packaging gas, etc.

Natural strong hydrophobicity, the highest quality gas sterilization filter material.

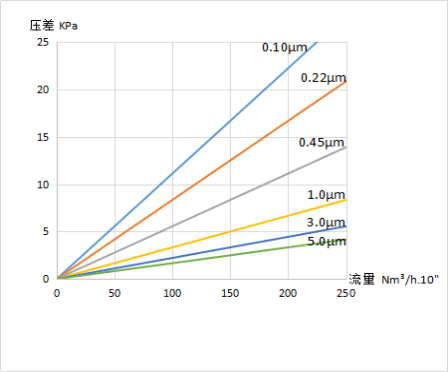

High flow rate, low drop pressure.

Each filter cartridge is equipped with a test certificate.

Free of resins and surfactants, broad solvent compatibility

No surfactants or binder resins

Sterile gas exchange of pure water tank vent filter in water treatment industry

Particle removal of organic solvents, chemical products, particle removal of high-purity chemical reagents

Sterile gas exchange for tank vent filter in the food and beverage industry

Sterilization filtration of fermentation gas in the biological fermentation industry .

Sterile gas exchange for vent filter of pure water tank , water injection tank and batch tank in the biopharmaceutical industry;

Fermentation gas sterilization and filtration in biological fermentation industry

Sterile filtration of solvents and media

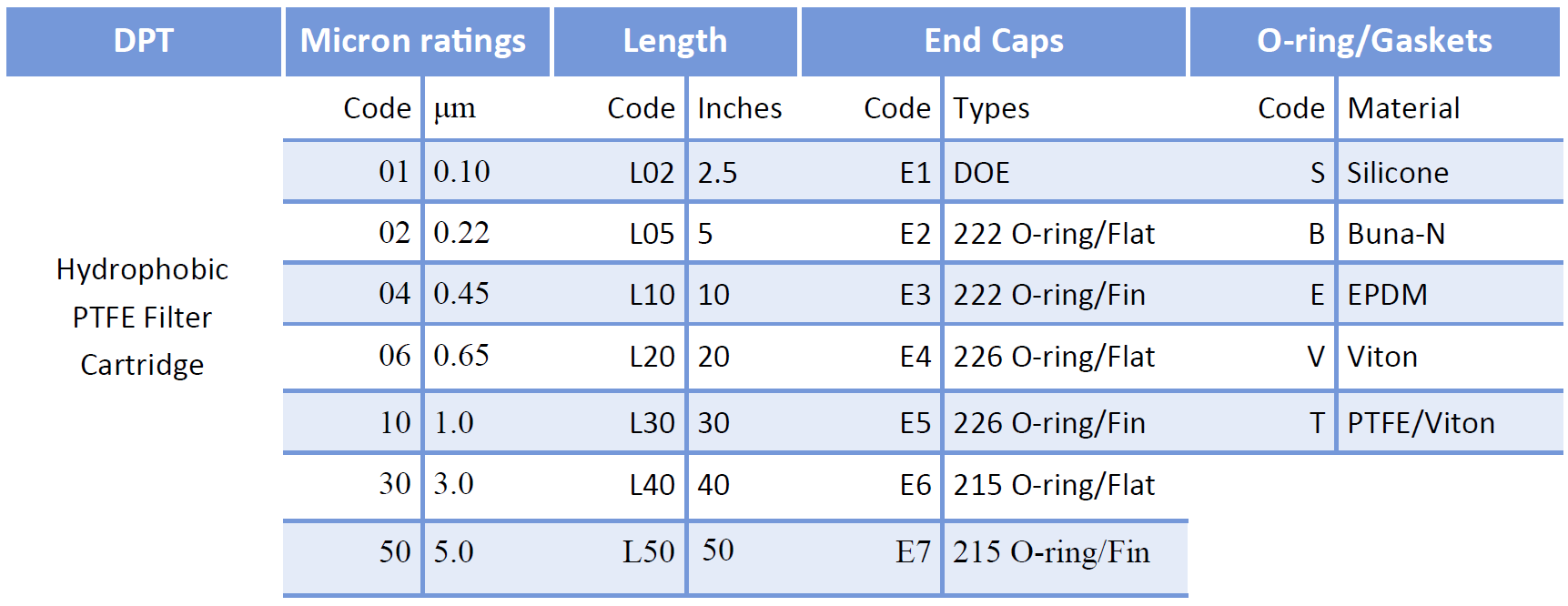

Filter Media | Hydrophobic PTFE |

Support diversion layer | PP |

Extended/Center core | PP |

Interface lining | No or stainless steel |

O-ring material | Silicone,Viton,EPDM,Buna-N |

Maximum working temperature | 80℃ (△P≤0.10Mpa) |

Maximum working pressure | Forward 4.2bar;Reverse1.5bar (25℃) |

PH range | 1-14 |

Cleanliness | The product itself does not have any foreign matter such as particles, fibers, etc. |

Biosafety | All ingredients meet USP (United States Pharmacopeia) Class VI plastic testing |