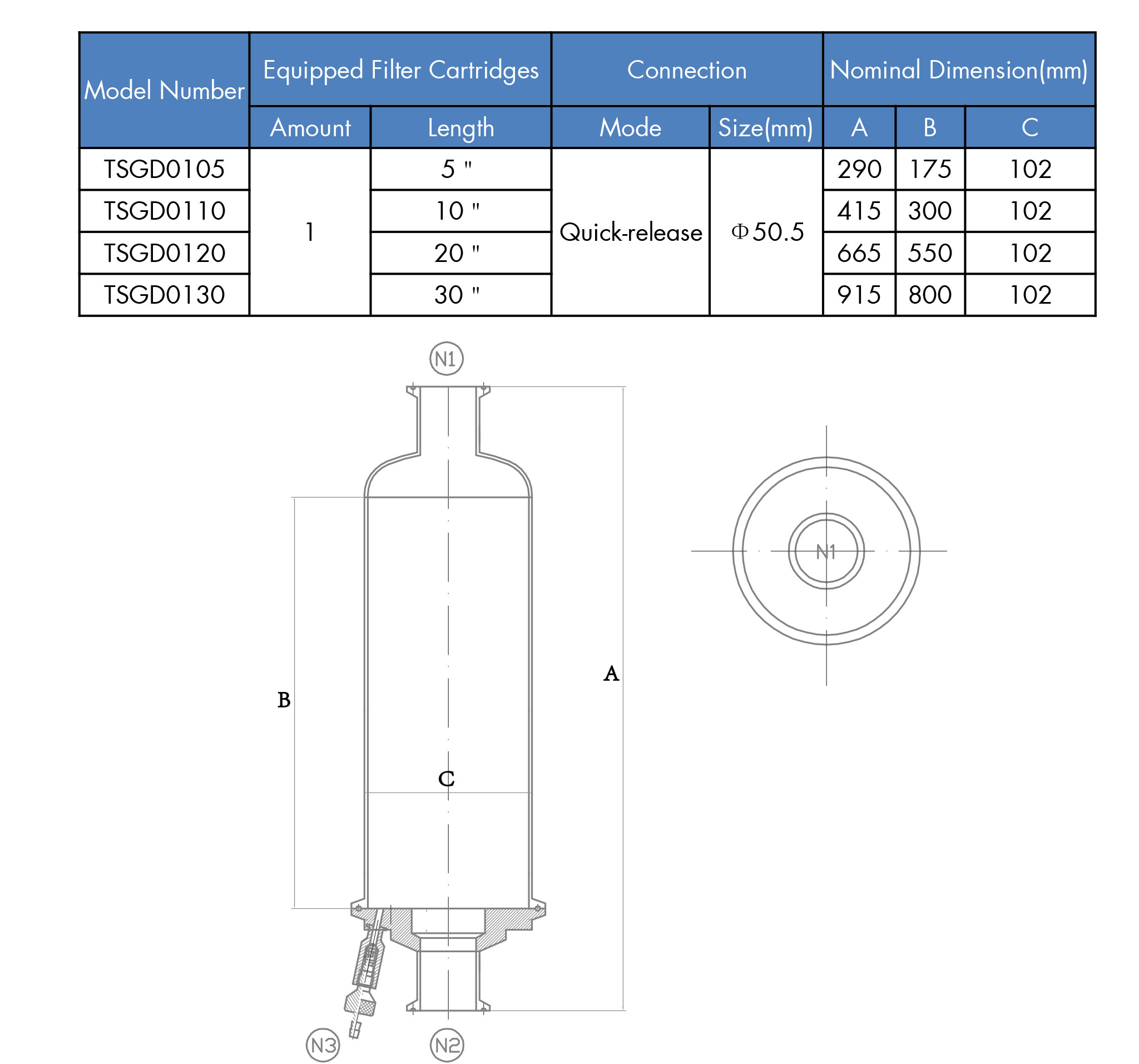

Tanvi in-line filter housings are designed to meet the requirements

of the bioparmaceutical industry.All 316L or 304 stainless steel

construction with polishing offers excellent cleanability features.

There is a sanitary drain valve ensuring proper liquid drainage

during application and industry standard 222 or 226 style

cartridges can be accepted.

Features and Benefits

Crevice-free polished surfaces and fully self draining

No dead corner

Low hold-up volumes for maximum product recovery

Quick fit type connections for easy filter integrity testing

Easy to use low point sanitary drain valve

Range of options to aid use in automated production systems

Material | 316Lor 304 stainless steel |

Surface treatment | Mirror polished or electrolytic polished |

Design pressure | 1.0Mpa |

Max. operating pressure | 0.8Mpa |

Design temperature | 20℃~150℃ |

Seal style | O-ring or flat gasket |

Barrel connection | Thread, clamp, flange |

Element connector | DOE, 222, 226,116 |

Thickness | 2mm |

Inlet/Outlet inner diameter | 1 inch/1.5inch |

◆ Sterile air/gas filtration

◆ Food and beverage processing

◆ Vent Filter