Lenticular Module filtration is a filtration method that utilizes depth media, it eliminate the hassle and mess that plate and frame filters can cause. Sanitary stainless steel lenticular housings are designed to meet the hygienic quality standards for depth filtration in the food and beverage, cosmetics, electronics, pharmaceutical and chemical industries.

Sanitary stainless steel lenticular housings are highly mirror-polished inside and out, make it with excellent corrosion resistance while also minimizing adhesion of process fluids to the inner surface, making cleaning operations easier. The complete disassembly housing design allows for easy cleaning, drainage and sampling of all internal surfaces and is designed with a secure rotating bolt closure. The housing accommodates 12.0- and 16.0-inch diameter lenticular discs in a variety of stacking heights, providing options for a variety of filter media areas and flow rates.

Tanvi Lenticular filter housing is designed to suit the most popular lenticular filter module from Pall, CUNO, EATON BEGEROW, SATORIOUS. For both DOE (Open on double), and Double O-ring, Plug in module. They are all made of food grade 316L (or 304) Stainless steel and surface finish meets the sanitary grade requirements.

Enclosed design eliminates the mess and product loss associated with dripping plate filters.

Simple to load and operate - no need for wetting and re-tightening.

Increased process safety and product quality; no drip losses; minimum operator exposure to process fluids

No fiddly gaskets to lose or huge stack of plates to clean & sanitize.

Vertical orientation requires less space to operate and store.

Housings can be loaded with as few as one filter module

Filter modules can be back flushed and reused multiple times

Sanitary design constructed of SS 316L

Suitable for small through large batch sizes

Housings can be steam sterilized in Situ or autoclaved

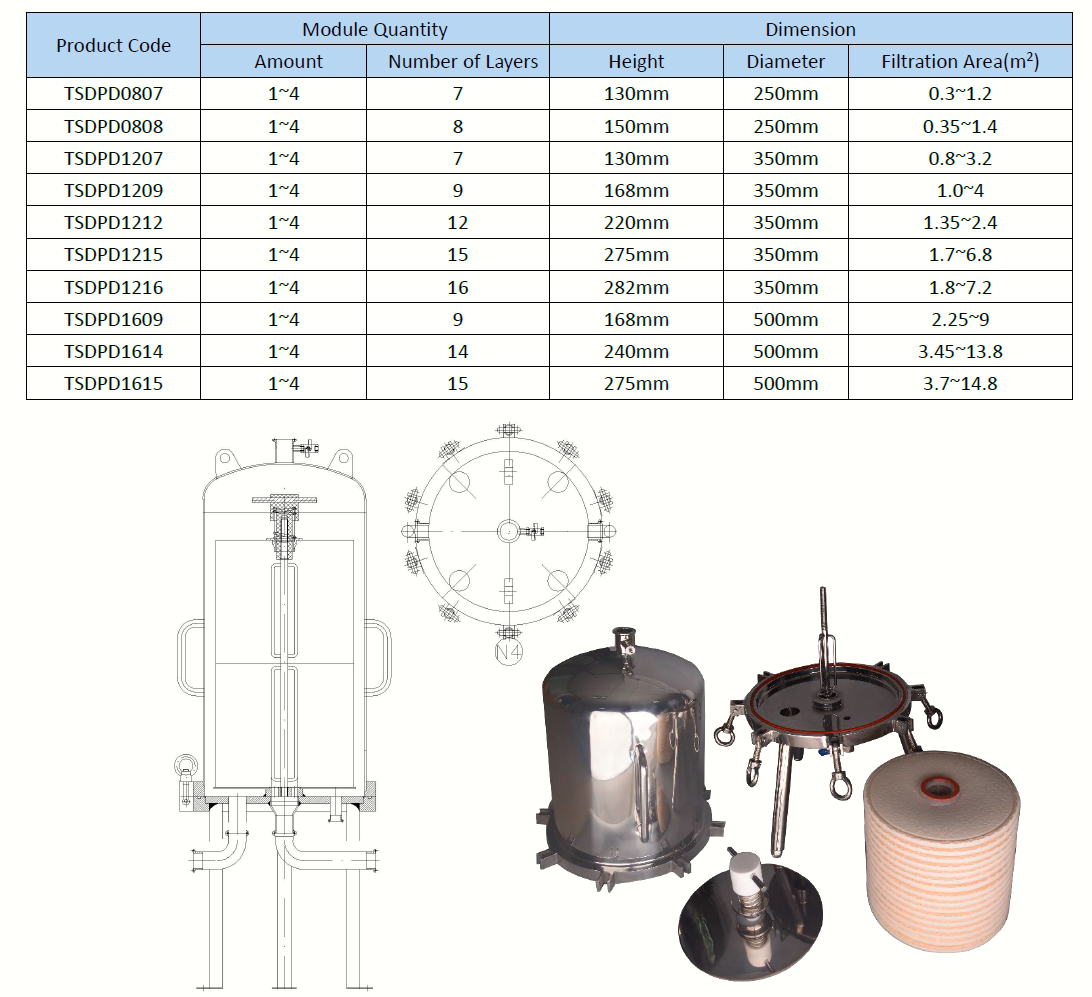

| Material | SS304; SS 316L |

| Module quantity | 1~4 |

| Diameter | 12" or 16" |

| Adaptor type | Plug in or Flat Gasket |

| Suitable module brand | Pall; Cuno; Begerow, Satorious, etc |

| Seal Material | Silicone, EPDM, Viton, NBR |

| Surface Polishing | Mirror Polish Ra<0.4um (EP as option) |

| Vent & Drain Port | Hose Barb / Tri-clamp. or as required |

| Design Pressure | 0.8Mpa |

| Working Pressure | 0.6Mpa |

Ø Microorganism and particle reduction in wine, enzyme solution, sugar syrups and beer.

Ø Final filtration of juice and juice concentrate prior to bottling

Ø Pre filtration of juice prior to final membrane filtration

Ø Clarification of wine, enzyme solution, liquor gelatin, olive oil

Ø Particle Removal

Ø Polishing Filtration

Ø Filtration after Stabilization

Ø Pre-filtration prior to Final Membrane Filters

Ø Reduction of Alicyclobacillus Acidoterrestris

Ø Final Filtration